Amasia Theme: Sustainable Supply Chains

How do we help make supply chains for consumer consumption far less wasteful?

At Amasia, our investment philosophy is centered around behavior change as a means to fight the climate crisis. This starting point drives our five investment vectors, which we call the sustainable themes: AI & Data for Sustainability, Circular Economy, Sustainable Supply Chains, Sustainable Cities, and Clean Energy Transition.

These represent the key areas where we believe behavior change can have the greatest impact in fighting the climate crisis. This is a different way of thinking about a VC investment thesis, and so we are writing a series of blog posts to explain each in more detail.

We’ve explained our approach to shifting to circular and more environmentally-friendly consumption patterns in our Circular Economy blog post, and in our latest blog post on Sustainable Cities, we discussed tackling the emissions of the built environment and transportation.

Our next theme in the series is Sustainable Supply Chains: How do we make supply chains far less wasteful? In other words, how do we shift from a wasteful, degenerative supply chain to a regenerative, resource-efficient one?

Typical supply chains are emissions-intensive, wasteful, and insight-poor

Supply chains are the lifeblood of today’s economy, producing and distributing goods and services worldwide in a complex web of interconnected systems and processes. However, activities along the supply chain, from highly-pollutive raw resource extraction to inefficient last-mile delivery and poor waste management logistics, impose significant environmental burdens.

These include high GHG emissions, natural resource over-extraction, pollution, and waste generation. A typical consumer company’s supply chain accounts for over 80% of its GHG emissions and over 90% of its impact on air, land, water, biodiversity, and geological resources.

Fig. 1: The environmental impact of supply chains; Source: McKinsey Sustainability

GHG emissions and resource extraction, however, aren’t the only issues that must be contended with. One of the biggest contributors to supply chains’ environmental impact is the massive amount of waste that they generate. Across all global supply chains, over $163 billion worth of inventory — 8% of total inventory — is thrown away yearly due to expiry or overproduction. Expiry and overproduction are driven by many factors, including inventory mismanagement, outdated systems, transportation and storage issues, and difficulty estimating and managing demand.

These challenges are partially due to the fact that many companies lack a systematic way to track inventory, relying instead on manual tracking; in fact, 73% of supply chain managers still use manual spreadsheets or outdated software to track inventory.

Moreover, increasing material shortages are encouraging a shift from a Just-in-Time (JIT) inventory model (goods are produced only as needed) to a Just-In-Case (JIC) model (companies keep large inventories on hand). While a JIT model inherently minimizes waste by actively adjusting supply to match demand in real-time, the JIC model relies on overproduction to mitigate the risk of stockouts.

We need to tackle supply chains inefficiencies, for both people and the planet

Prioritizing sustainability and transparency requires us to reimagine how supply chains can meet businesses’ and consumers’ needs in the least resource-intensive, emissions-heavy, and waste-generating way possible.

Enter our theme, Sustainable Supply Chains. Under this theme, we look at companies that rethink traditional supply chain management approaches, and enable us to move away from siloed systems and processes to a more integrated, data-driven model. These companies’ software solutions can be leveraged by actors along the supply chain, helping to minimize inefficiencies and optimize networks, processes and inventory.

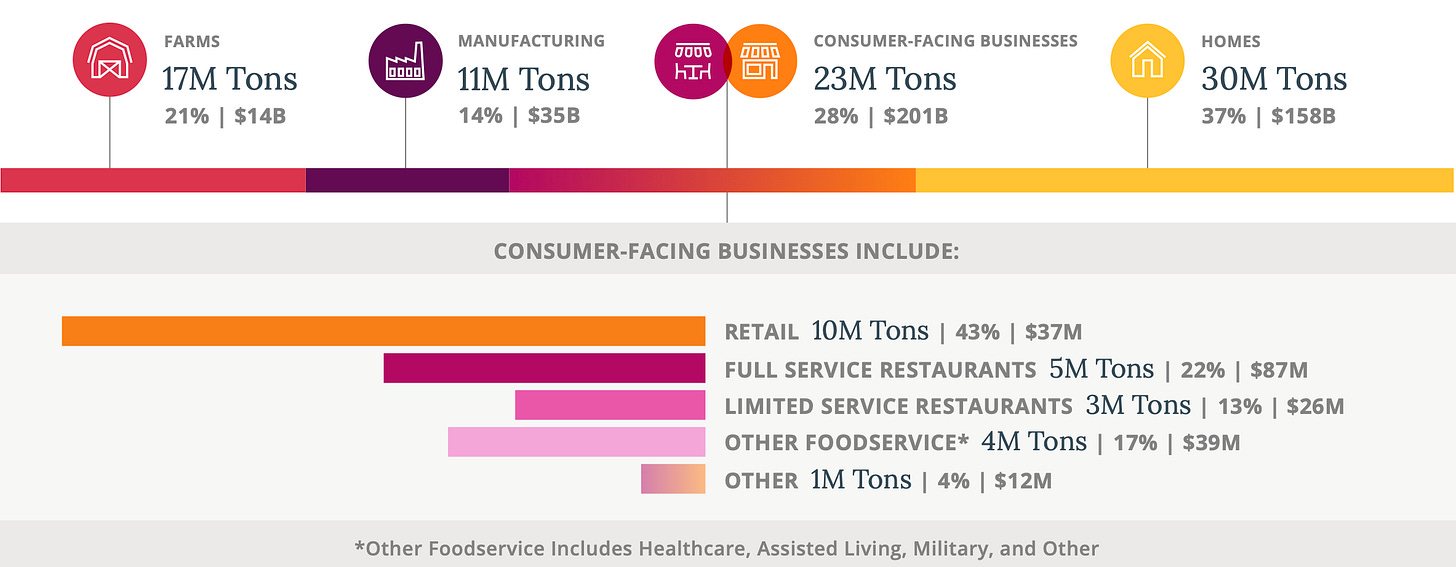

Fig. 2: Where food waste occurs along the supply chain; Source: ReFED

How can companies solve supply chain challenges?

Software companies hold great potential in shifting behavior across the entire supply chain. We see three broad areas to address these shifts: planning, visibility, and management. In other words:

How do managers plan waste out of the supply chain?

How do managers manage the movement and conditions of inventory across each stage of the supply chain?

And how do managers gain visibility over their processes and suppliers to ensure environmental standards are met across the full scope of a company’s value chain?

Software that enables better planning includes demand forecasting and route optimization software for planning delivery routes and times. Inventory and waste management software help leverage data to increase real-time visibility of inventory location and quantity, greatly easing inventory management across the supply chain. Lastly, software can aid in increasing visibility across the supply chain: supply chain mapping and supplier collaboration software can play a significant role in streamlining processes and communication.

Fig. 3: Supply chain transformation prioritized by a majority of firms; Source: Bloomberg

The Sustainable Supply Chains companies in our portfolio demonstrate how software and software-enabled companies can effectively cut supply chain waste and inefficiencies. For example, TreeDots in Singapore is a B2B platform leveraging technology to match food supply and demand, procuring surplus and imperfect food and redistributing them to users at affordable prices. This helps prevent food waste and associated emissions.

Shortening supply chains can also mean significantly reducing emissions, especially from transportation. In eastern Indonesia, Super enables affordable access to consumer goods to rural populations via its network of community-based agents and logistics centers. Agents sell products directly from manufacturers to customers through its app, cutting out many layers of middlemen and reducing associated emissions.

How we view supply chain solutions also applies to a plethora of B2C companies — supply chains that lead up to individual consumers can and should also be reconstructed. One such company in our portfolio is Living Food in India, which provides healthy meals made with locally sourced, high-quality ingredients to consumers through its cloud kitchens and offline outlets. Living Food reduces delivery emissions by sourcing local ingredients, and minimizes waste and plastic use.

Conclusion

The ideal supply chain is transparent and traceable, with full end-to-end visibility, ranging from the extraction of raw materials to the end-of-life of a product. This transparency allows businesses to identify areas of inefficiency and environmental harm and take corrective action, reducing waste and emissions.

Such supply chains could allow businesses to identify and track progress toward environmental goals, and empower consumers to make informed choices about the products they purchase, thus dramatically changing the way we produce and consume goods.

Many thanks to the Amasia Summer 2023 Fellows, Alannah Nathan and Nazli Dakad, for supporting the research and writing that went into this essay.